Building the Best

Version of Your

Invention.

How much demand is there for my product? Am I targeting the right audiences? These are the questions you’ve probably asked yourself while refining your invention idea. Successful inventors take this a step further. To get the right answers to these questions, they understand that real feedback on their product is far more valuable than conclusions drawn from market research alone. That’s why prototyping is so important. Prototyping is how you get tangible products in your customer’s hands and the flexibility to make quality updates rapidly, efficiently, and affordably.

Have a product idea?

Let’s chat.

What are Product Prototype

Development Services?

Prototyping is the agile process of building an iteration of a product to measure customer feedback and learn how to best optimize and improve the product to help ensure business success.

Let’s think about our own purchasing experience – the way we compare and validate products to determine what’s right for us. We often gravitate to products that simply look great and then judge the quality based on touch, feel, weight, and how easy it is to use. Knowing this, inventors need to apply the same logic to their own products to deliver the best possible experience for their customers. From broader decisions like how fast the product functions to the finer details like exterior material, business success is not solely determined by what you think is right. It’s determined by the voices of your customers.

Prototyping Development Services

MAKO’s end-to-end prototyping capabilities include the following services below and more. Have a question about these services? Feel free to contact us with your prototyping inquiries.

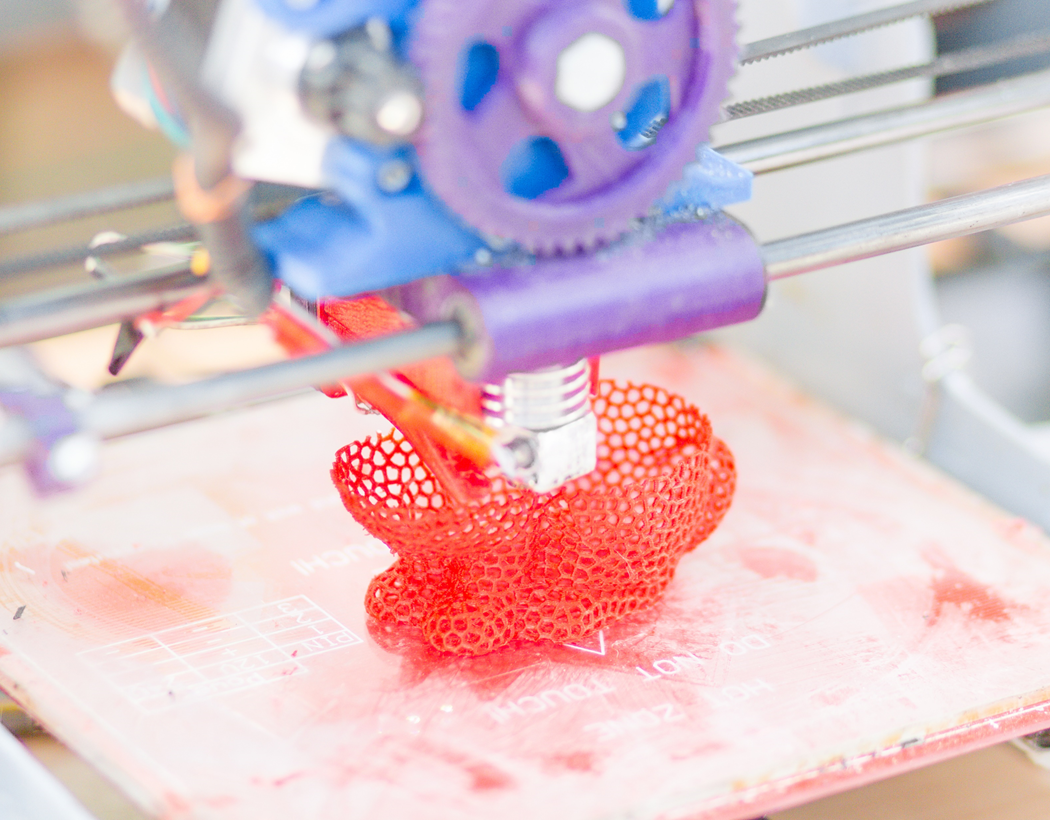

- Additive manufacturing

- Short-run manufacturing

- Mock-up prototypes

- Concept prototypes

- Cosmetic prototypes

- Feasibility prototypes

- PCB and electronic prototypes

How Product Development Prototype Services Work: Our Process

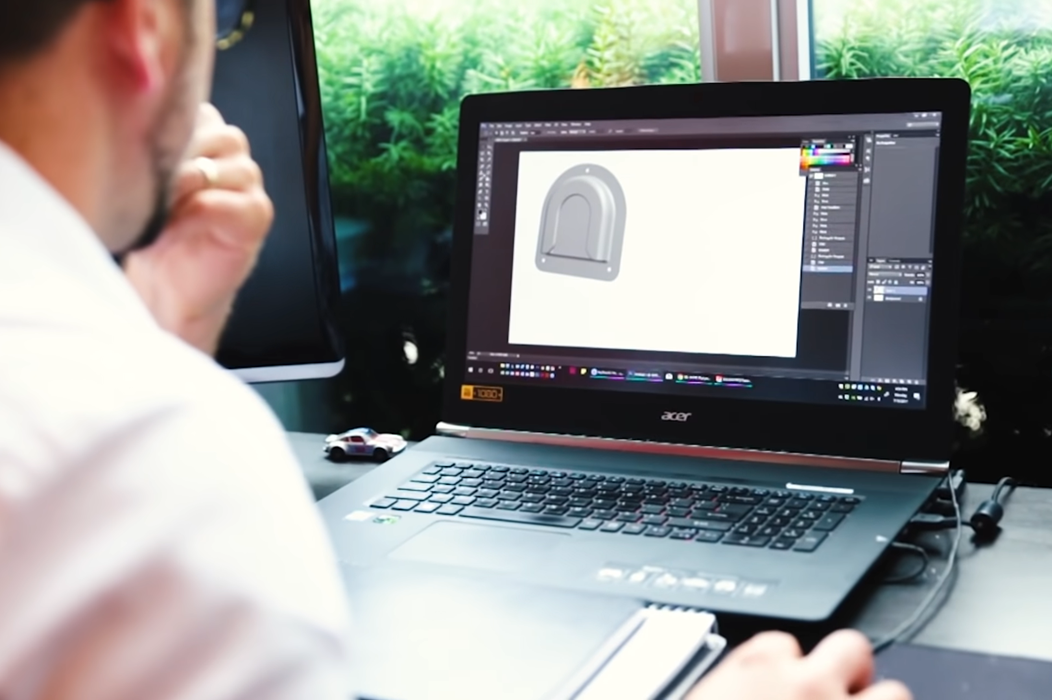

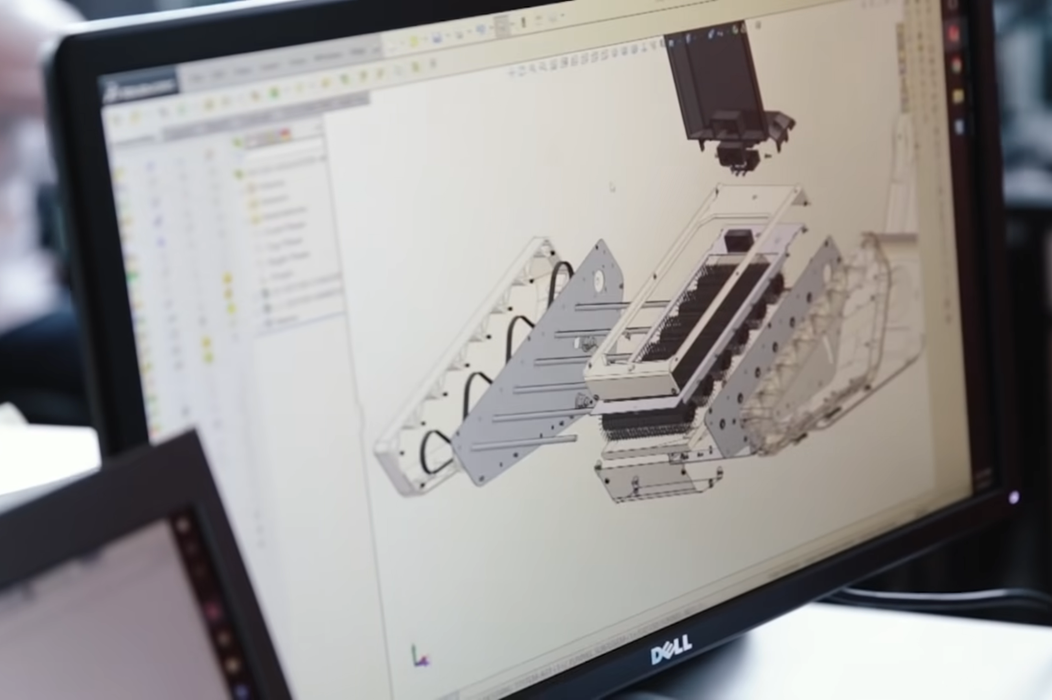

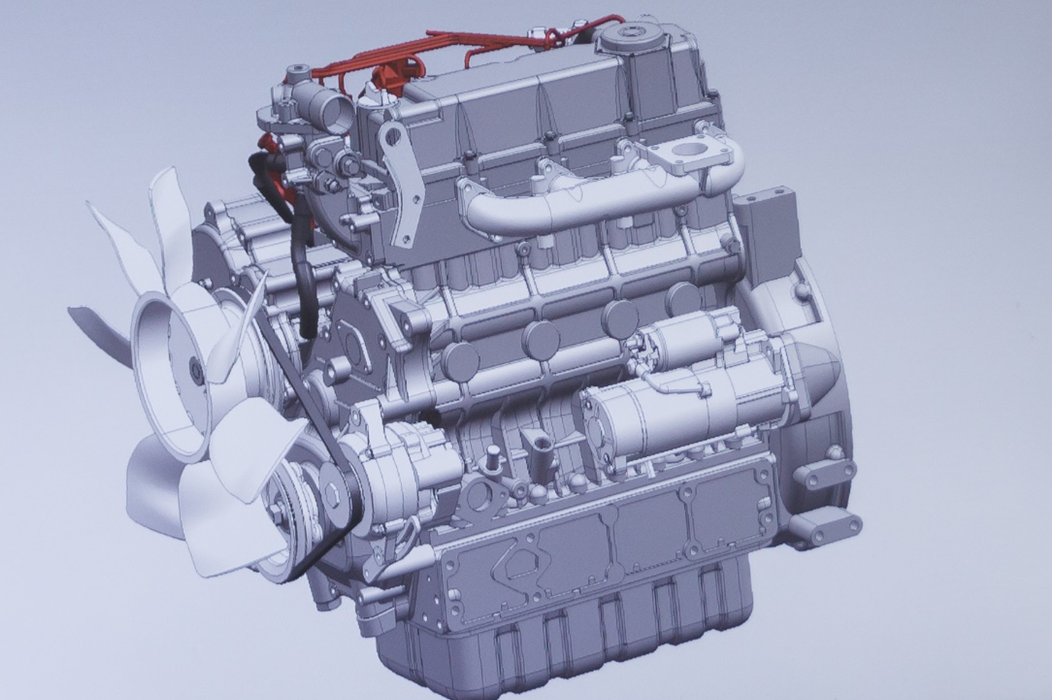

Every prototype starts with a computer-aided design (CAD) of the product. We provide product design services and industrial design services to build the CAD. The CAD is a comprehensive 3D model of the invention and incorporates the functionality, dimensions, materials, and all other internal and external information about the product; it’s the reason why prototypes are essential to product design. We then can run computer simulations to learn what happens to each individual part and component when in use and in assembly, how well the product functions, and the ease of small and large-scale product manufacturing.

With the CAD as the foundation, we then manufacture a prototype to learn about your product in real-time in a real space. To get that information, MAKO can prototype your product as a whole, or isolate and build individual elements of the invention to help you make the right decisions for your product. Because when your customers hold the prototype in their hands for the first time, they might feel like it’s too heavy, that they like the feel of the exterior, or that the ergonomics could be improved. Whatever the feedback, you won’t know what they like until they try it.

The versatility and importance of prototypes don’t end there either. By producing and selling small batches of high-fidelity prototypes to real customers, you can prove that your product has traction to draw the interest of investors. You can also reach out to MAKO for patent referrals to protect your idea or even start building cosmetic prototypes to help ramp up your marketing initiatives.

1. 3D CONCEPT CAD DESIGN

CAD / RENDERINGS

The CAD design phase is taking the refined sketch from above and then using state-of-the-art 3D CAD software to build the initial conceptual CAD design of your product. Even though this is just conceptual at this point, at MAKO, we start the building of these models with full manufacturing-grade top-of-the-line software such as Solidworks Premier or Fusion360. This requires more technical expertise; however, it makes the design and engineering process far smoother, and far easier to jump into manufacturing (and creates far more product value in the design along the way). Also, we’ve curated a library of components and experience from over 1,000 product designs, all developed in-house, so we’re extremely efficient and effective at 3D CAD Design as it is the key part of the mechanical and electrical engineering services process.

2. SIMULATION ANALYSIS

ASSESS / OPTIMIZE

The question we’re trying to answer here is: “Can we make it better and more cost-efficient?” This phase is all about identifying the limitations and improvement opportunities through rigorous 3D virtual simulations of the product in various static and dynamic settings. For electrical engineers, they can simulate the type of wiring, voltage, and heat output depending on how much electricity is required to power the component or device. Identifying these critical electrical engineering elements is the key to building functional prototypes, reliable manufacturing runs, and getting your ideal version of the product in your customers’ hands.

3. PROTOTYPING

BUILD / MEASURE / LEARN

The purpose of the CAD is to confirm that the product design is feasible and functional from a virtual perspective. The product prototyping phase gives you the opportunity to hold and use a tangible product to learn how the product looks and functions in the real world. Prototyping also gives you the opportunity to refine and perfect the final design to minimize costs and risks before going to full production. Whether it’s iterative, parallel, rapid prototyping, or our very own Smart MVP process, our prototyping processes are designed to help ensure you’re ready for user testing, investment pitches, crowdfunding, and everything in between.

How MAKO’s Prototype Development Services

Can Build Your Business

SMART MVP

Want to get to the core of what your customers really want? That’s what the minimum viable product (MVP) is for. Minimize unnecessary time wasted, costs, and work by focusing on a prototype that functions well without any of the distracting bells and whistles. Simplicity is key here because the sole purpose of building an MVP is to get valuable feedback from early adopters. Thus, the MVP is the cornerstone of our iterative product development services process – the building blocks of making the best possible iteration of the invention. And thanks to advancements in our industry like 3D printing, manufacturing the MVP can be done locally plus more affordably and quicker than ever before.

RAPID PROTOTYPES

The advantages of rapid prototyping explained below highlight the reasons why quick is sometimes better than complicated. When you need to learn about how a specific aspect of your invention performs in the real world and you needed it yesterday, rapid prototypes are the way to go. For example, we can craft specialized components to quickly learn how well it fits the product and if it improves functionality. Rapid prototypes are especially important to help mitigate risks, ensure feasibility, and for comparative performance analysis.

HIGH-FIDELITY PROTOTYPES

High-fidelity prototypes are especially useful for when you’re nearing launch and finalizing the last details of the product prior to manufacturing. Using Production-level cosmetic prototypes, inventors can showcase beautiful shots of their product on their marketing channels to excite their audience well before launch. Those in search of the right investors will often sell near-final prototypes of their invention to prove that the product has traction in the market.

Prototype Development Services Tailored to Your Needs

MAKO Design has spent over 20 years creating, testing, refining, and perfecting the prototyping process required to create global caliber products, specifically for startups, small manufacturers, home inventors, & eCommerce brands. Through our intense focus specifically on product design services for small businesses, we ensure perfect alignment with your product vision and help you succeed in every way. Our product design services are tailored to designing your product to a modern and top-tier caliber while also being able to execute quickly and efficiently, all at small business budgets. We created this product development niche back in 1999, and we’re still leading it today focusing on that same business model over 20 years later.

FOR HARDWARE STARTUPS

Whether you’re an early-stage startup or getting ready to scale, we’re here to transform your idea into a product design to help you disrupt the existing market, along with the many product market connections you’ll need along the way. MAKO is your one-stop-shop for it all, in addition to connecting our clients with some of the industry’s leading players in the hardware startup space.

FOR SMALL MANUFACTURERS

We are the original product design services firm tailored to small product businesses, so why not work with the best for your next big product? Whether designing something completely new, revitalizing your existing products, or improving something that already exists, MAKO provides world-class design at small business pricing and timelines.

FOR ALL HOME INVENTORS

No ask is too big, no detail is too small. We’re here to collaboratively design your product for success. As a new inventor, MAKO has the most comprehensive set of support services, industry connections, and guidance to help your product be a huge success. We guide you through the entire process, then set you up with direct connections to some of the best product sales brands on earth.

What’s Next after Prototyping is Done?

If you want to see your idea fully come to fruition, manufacturing is the next logical step once prototyping is complete. As such, we may have to return to the CAD to include the changes made in the prototyping phase. Most importantly, however, the finalized CAD must be designed for manufacturability. Meaning, not only does the product function well as a whole but also helps ensure the product can be assembled with ease. In addition to manufacturing, inventors may pursue licensing or fundraising, all three options are outlined below:

OPTION 1:

CONTINUE DEVELOPMENT

TO MANUFACTURING

The way most new inventions become successful products is to get to manufacturing and selling products. Once engineering is done, MAKO Design can complete the prototyping and manufacturing of your invention for you. We are a one-stop-shop from sketch to production then to sales. Half of our products are physical inventions, the other half are electronics products. Either way, we’re a full-stack in-house development firm. Below is a full list of all steps to get your product to production and then get your product out to market buyers!

OPTION 2:

LICENSE YOUR PRODUCT

TO A BRAND

Some inventors just want to get their product designed to a point where they can then license their invention idea to an existing product brand. Either way you go, completing world-class product design is a critical first step. If looking to license directly after design, MAKO would then set you up with a patent attorney so you can protect your IP before pitching your idea to licensors. Keep in mind that the further you develop your product, the higher the probability of licensing, so you may want to have MAKO engineer and/or prototype your design before you start pitching to get a licensing deal.

OPTION 3:

RAISE INVESTMENT TO

CONTINUE DEVELOPMENT

Raising money is a very normal part of getting a hardware product off the ground, and with MAKO’s help, anyone can do it! In fact, half of MAKO’s clients don’t start with enough funds to complete development and manufacturing. First and foremost, before raising any money, even from friends and family, it is essential that you complete at least the product design portion yourself. Even then, the further you push into engineering and especially prototyping, the better you look to investors, the more money you can raise, and the less equity you will have to give away.

How Prototyping Services Fits into MAKO’s Overall Product Process

1. PRODUCT DESIGN

This includes industrial design. This is the first and most important step in the product development process. This is the foundation of all product development to come, so is critically important to have it done right.

2. ENGINEERING

Mechanical engineering services and electrical engineering services (for those products with electronics) are the detailed work on the CAD to ensure that all components of the product design work cohesively, reliably, and predictably.

3. PROTOTYPING

This is the current phase! Before the product reaches the market, it’s important to test the form and functionality with a prototype. Prototypes are also a great way to generate traction for marketing, pre-sales, crowdfunding, and financing initiatives.

4. PATENTING

We have preferred connections and pricing with a network of patent attorneys to help our clients with all things related to IP (Intellectual Property) protection. Our clients get quality patenting work, affordably through our network of US and Canadian patent attorneys.

5. MANUFACTURING

Once the prototyping and engineering are complete, tested, and refined, the product is ready to move to production. This may happen after preselling through crowdfunding, or before selling if you choose to sell direct to buyers once you have inventory in stock.

6. SELLING

MAKO Design has many connections to help our clients launch and sell products. There are three main options: Pre-selling through crowdfunding, bulk order sales directly to wholesalers, distributors, retailers, and/or direct to the end-customer.

Prototype Development Services: Frequently Asked Questions

Here are a few of the most frequently asked questions about MAKO’s prototyping development services. Don’t see an answer to your question here? Feel free to contact us anytime with your inquiries, read our blog for hundreds of articles related to prototype development and product design services, learn about the entire end-to-end process with MAKO’s free invention kit, or check out the industry’s largest podcast: The Product Startup Podcast.

Prototype development is the process of working on an iteration of the product specifically to optimize user experience, manufacturability, and costs.

Almost all prototypes require a CAD file to be made. This CAD file is a 3D model of the product which also houses critical information about the product including, size, functionality, materials, and more. Using the CAD file, we can then build and assemble individual parts or the entire prototype to measure and learn how to best optimize the final design.

There are multiple ways of turning an idea into a real product. Some clients come to us with an extremely rough prototype using off-the-shelf bits and pieces. Others may come to us with just a sketch on a napkin. Whatever you chose, the first step is to ensure our clients sign an NDA to have confidential and secure discussions surrounding your invention idea and proprietary information.

Let’s Chat

Use the form below to let us know how we can help.

We’ll get back to you within one business day.