Imagine you’ve decided to re-organize your closet, but instead of leaving your house, traveling all the way to the store, and measuring the storage bins that are available, all you need to do is enter the measurements of the bin into your computer and print them out right there!

For a leading prototype design firm, this is our reality. We regularly use 3D printers to create prototypes, evaluate functionality, and improve product 2.0. So here’s a quick overview of the different ways our prototype design firm and consumer hobbyists use 3D printing.

3D printing and fashion are merging creating new fields of business for all prototype design firms.

3D Printing for Our Prototype Design Firm

The most common form used by a prototype design firm uses inkjet technology, where nozzles in a 3D printer move back and forth, dispensing a fluid. Instead of ink, these printers dispense thick waxes and plastic polymers, which solidify to form each new cross-section of the object.

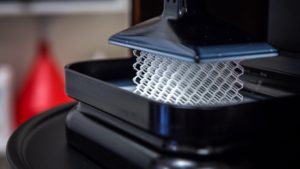

Binder 3D Printing:

A 3D printer creating an intricate design using binder technology.

This version uses two separate materials that come together to form each printed layer: a fine dry powder plus a liquid glue or binder. Binder 3D printers make two passes to form each layer. The first pass rolls out a thin coating of the powder, and the second pass uses the nozzles to apply the binder. This version of 3D printing tends to be faster, which for any prototype design firm is always a plus. Another major advantage is you can incorporate a wide variety of materials like metals and ceramics.

Photopolymerization:

A 3D printing technology whereby drops of a liquid plastic are exposed to a laser beam of ultraviolet light, which converts the liquid into a solid.

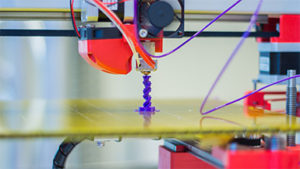

Selective Laser Sintering:

Another example of the intricate products 3D printers produce.

SLS relies on a laser to melt a flame-retardant plastic powder, which then solidifies to form the printed layer. One of the biggest advantages of SLS is the high level of precision it can achieve. As a prototype design firm, we require incredibly precise prototypes for our clients, especially those in the medical and safety fields whose products are literally life savers.

3D printing is becoming more and more common, expanding from industrial users like us to consumer hobbyists like you. Let us know which 3D printing method you’ll use!

About: MAKO Design + Invent is the original firm providing world-class consumer product development services tailored to startups, small manufacturers, and inventors. Simply put, we are the leading one-stop-shop for developing your physical product from idea to store shelves, all in a high-quality, cost-effective, and timely manner. We operate as one powerhouse 30-person product design team spread across 4 offices to serve you (Austin, Miami, San Francisco, & Toronto). We have full-stack in-house industrial design, mechanical engineering, electrical engineering, patent referral, prototyping, and manufacturing services. To assist our startup and inventor clients, in addition to above, we help with business strategy, product strategy, marketing, and sales/distribution for all consumer product categories. Also, our founder Kevin Mako hosts The Product Startup Podcast, the industry's leading hardware podcast. Check it out for tips, interviews, and best practices for hardware startups, inventors, and product developers. Click HERE to learn more about MAKO Design + Invent!

Alisha Ross

November 13, 2019 at 4:17 amI’m so happy to read this. This is the kind of manual that needs to be given and not the accidental misinformation that is at the other blogs. Appreciate your sharing this greatest doc.

MAKO Design + Invent

November 13, 2019 at 11:06 amThanks Alisha! So glad to hear you’re enjoying our work. Keep reading for more great posts!