The exercise of building a prototype model in design engineering is almost like using Siri. You have the ability to translate complications, send cues, and solve a problem. Not to mention, a prototype in the engineering design process, just like Siri, works habitually.

For instance, engineering prototype design is used in almost every sector of its industry in some form. This includes aerospace, computer, mechanical, environmental, and so forth. However, the prototype engineering design process is so much more than pushing a button with instant results.

What Is a Prototype Model in The Design Engineering Process?

First and foremost, a prototype is a working model of the product that is created for the purpose of testing before the invention is manufactured.

The engineering design process launches by troubleshooting engineering complications, market, and further background information, planning remedies, and evaluating all of the alphabetic backup plans.

Later, your engineering team will incorporate the information into almost a playlist to initiate the project. Sometimes, the mood of the product, or shall I say your engineering team assesses the potential of the invention in its environment. Prototypes are to navigate the unknowns so the outcome can be sound and one musical composition.

What Are Prototype Models Used For?

There are a lot of advantages to engineering prototype design, such as elevated user involvement. The model actually provides your consumers with a better understanding of how the system is being designed. It also allows you to develop customer loyalty and or continue to flourish. Consumer input really provides a chance to not only get clarity on the performance technically but also confirmation the product will be of use to your market.

However, there are some aspects of prototyping that one should look out for. The main point of course is finding a design and invention firm that is transparent and you can trust. Here at MAKO, we provide a comprehensive breakdown of our product prototyping service and what it includes to get an idea of how we are pioneering through the industry.

Types of Prototype Models in Engineering Design

Now that we have skimmed briefly through the outline of what prototypes and engineering design is, it’s time to break down the chapters a little deeper.

Rapid Prototyping

The exercise of rapid prototyping can actually make the process as swift as it sounds. It is there to create an ocular and working experience in a timely manner. Not to mention, it assists the engineering design team to form a variety of different methods, placing concepts into figures, and confirms the common thread during product design development. This approach will also reduce the opportunity for risks and not miss any necessary practices.

Evolutionary Prototyping

In this case, evolutionary prototyping is a formed DNA strand stemming from incremental and extreme models. It includes a sequence of prototyping refinements. The first sector is to curate and arrange the systems into multiple solo chapters. After this, your clients have the chance to view the model. Feedback will unite, so the product can proceed with further sifting until a sense of harmony is evident.

Incremental Prototyping

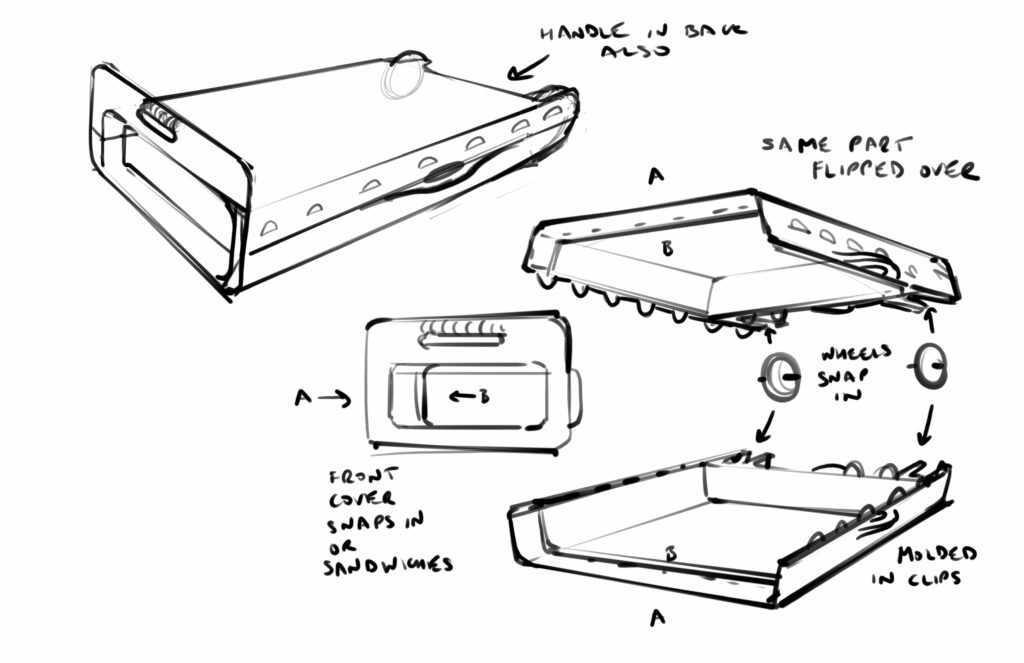

Incremental Prototyping revolves around dividing the untied forms of prototypes that were once made solid into richer modules. The cycles will undergo testing and be polished respectfully. It will then join forces into more of an encyclopedic unit. Your engineering team will be able to understand the equilibrium of aesthetics, demeanour, and idioms.

Production Prototyping

At this phase, you will now have a fully developed prototype that will be ready in terms of volume production. Each component of the product is formed through fragments that have previously reached its maturity through mass production techniques.

In some cases, select consumers will be employed to provide another source of validation during the product assembly process. It will then proceed to finalize the precise practicalities for pressing accessories.

Once your prototype has been given the green light, your product will be ready for mass production and launched into your products society.

Prototype Model in Design Engineering: Frequently Asked Questions:

Just like Wired’s Most Searched Questions interview series with various famous individuals, we at MAKO look to auto-complete questions in our industry that come right from the source:

Why are prototype models important?

Humans retain 80% of what they see compared to 20% of what we read and 10% of what we hear. Not to mention, visuals add a feature that communication and written and verbal techniques do not. Speed is the key factor since the brain can actually process images and videos 60,000 times faster than text.

This makes Prototypes extra special as they mock what the real and future product will look like to both you and your customer.

What do design engineers prototype?

Firstly, design engineers are there to confirm practical needs or display touch tones for the creation through more of a scientific lens.

Design engineers then develop models and or instructions for automation compatibility with other machinery. All of MAKO’s design engineers use their opulent knowledge to create prototypes for hardware startups, small manufacturers, and all home creators.

How do engineers build a prototype model?

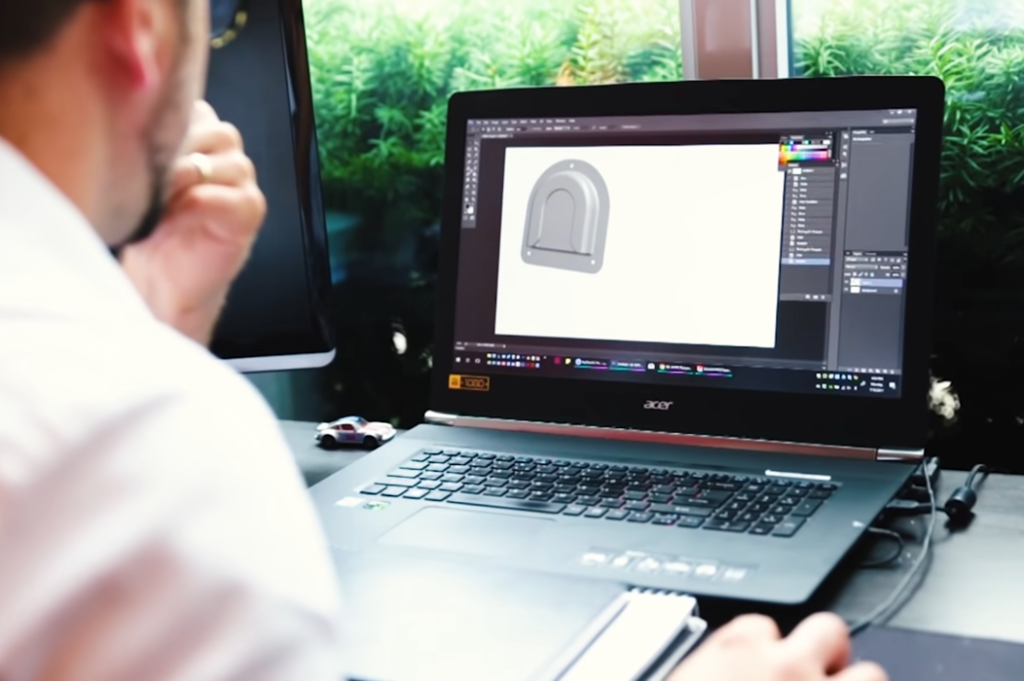

Computer-aided design (CAD) and or Computer-aided industrial design (CAID) software allows those mixtures of scientific methods to come alive. This can also include readily available materials and construction kits.

How do you find a design engineer for a prototype?

Just reading this MAKO-produced article is a great indicator that you’re already headed in the right direction. Our product prototype services include initial mock-up, concept, cosmetic, genuine, PCB and electronic prototypes, and so much more. MAKO’s highly gifted team will also ensure your prototype and any part of the developmental process are well-suited for product manufacturing.

Final Note

Creating a prototype in engineering design truly proves the power it has to be able to solve a problem, just like how your product will one day become a solution for your clients.

To learn more about our prototype engineering design process and services, visit makodesign.com and check out our services page.

If you have a great new invention idea and would like to schedule a meeting with our Product Strategy team to discuss feasibility and potential next steps, call +1 (888) 806-MAKO or fill out the form on our contact page!

About: MAKO Design + Invent is the original firm providing world-class consumer product development services tailored to startups, small manufacturers, and inventors. Simply put, we are the leading one-stop-shop for developing your physical product from idea to store shelves, all in a high-quality, cost-effective, and timely manner. We operate as one powerhouse 30-person product design team spread across 4 offices to serve you (Austin, Miami, San Francisco, & Toronto). We have full-stack in-house industrial design, mechanical engineering, electrical engineering, patent referral, prototyping, and manufacturing services. To assist our startup and inventor clients, in addition to above, we help with business strategy, product strategy, marketing, and sales/distribution for all consumer product categories. Also, our founder Kevin Mako hosts The Product Startup Podcast, the industry's leading hardware podcast. Check it out for tips, interviews, and best practices for hardware startups, inventors, and product developers. Click HERE to learn more about MAKO Design + Invent!

Foroogh

2023-09-25 at 1:28 pmHi, thank you for your useful explanation.

How much would be the range of cost for building a prototype model?

MAKO Design + Invent

2024-03-26 at 1:40 pmHi Foroogh,

Thank you for your comment! It is difficult to provide a precise range for the cost of building a prototype model without more details, as it largely depends on the complexity of the product you would like to build. MAKO offers comprehensive product development services all under one roof, including research, design, prototyping, patenting, and sales/distribution, so we have exponentially streamlined the development process and pride ourselves on working within the budgets of our clients. If you follow this link to our contact form and provide us with some information on your invention idea, we can set you up on a call with our product strategy team and offer a more precise cost estimate.

grprototypes

2024-06-17 at 5:57 amNice article , Thanks

MAKO Design + Invent

2024-06-17 at 11:28 amThank you for your comment! We’re glad you enjoyed this piece.